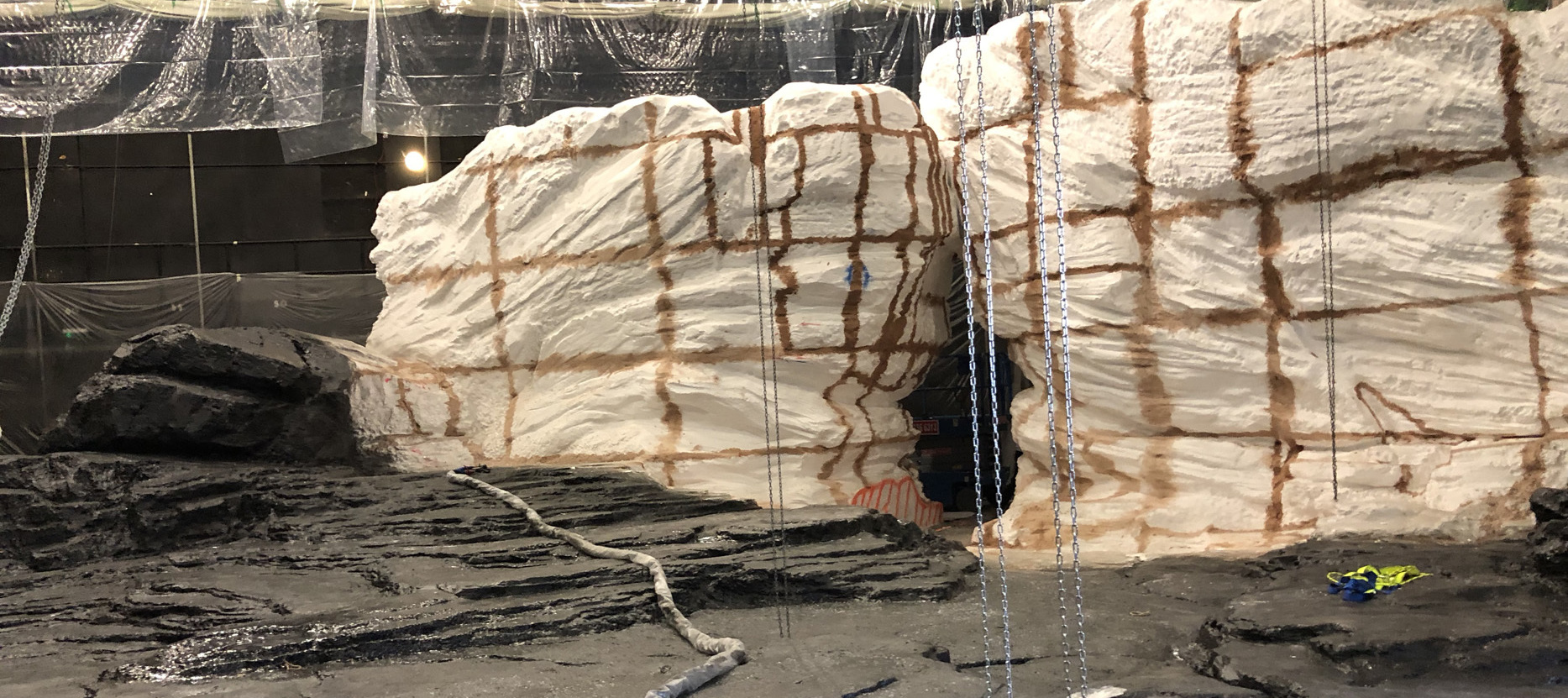

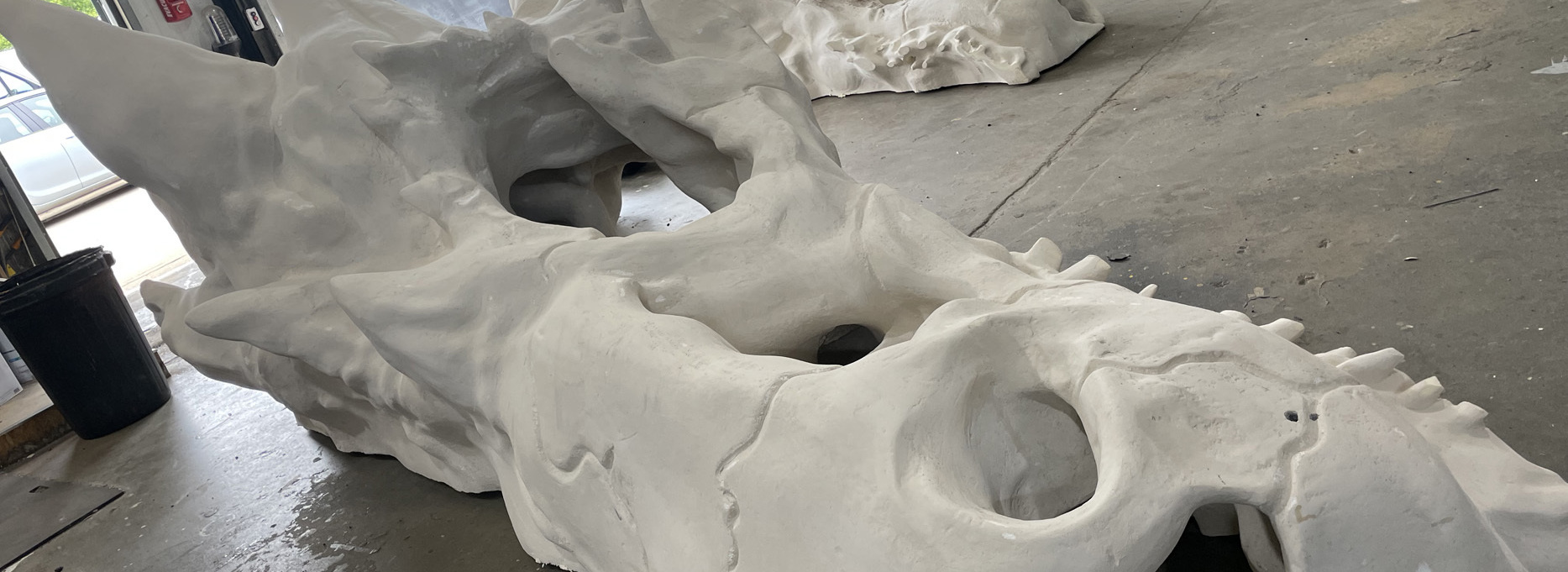

A: Polyurea & polyurethane coatings have a wide range of applications across various industries. They are commonly used for industrial flooring, truck bed liners, tank linings, waterproofing, corrosion protection, and hard coating of film props and scenery

A: Polyurea and polyurethane coatings offer numerous advantages, including high tensile strength, exceptional abrasion resistance, fast curing times, seamless and flexible application, high resistance to chemicals and UV radiation, and long-term durability. They also provide excellent protection against corrosion and can be applied to various substrates.

A: The curing time of polyurea coatings depends on several factors such as temperature, humidity, thickness of the coating and the formulation. Generally, polyurea coatings have a fast curing time ranging from as fast a 6 to around 45 seconds, allowing for quick turnaround times in projects.

A: Polyurea and polyurethane coatings can be applied to a wide range of surfaces, including concrete, metal, wood, fiberglass, and more. Proper surface preparation is essential to ensure adhesion and optimal performance of the coating.

A: Our paint booth is 9M Long, 4M Wide and 4M Tall giving us space to take on the biggest of projects. If you have anything bigger or bulkier – We can come to you with our mobile spray setup

A: Polyurea and polyurethane coatings are a type of protective coating that is formed by the reaction between an isocyanate component and a resin blend. It offers excellent durability, chemical resistance, flexibility, and waterproofing properties.

A: All of our coatings are applied at high temperature and high pressure using specialist spray equipment, it is not possible for you to apply them yourself.